Radio Golf Ball (ca. 1910-1930)

Mathew Laine, in A Cultural History of Radiation and Radioactivity in the United States, indicates that the Radio golf ball was introduced in 1910 by the Worthington Golf Ball Company "with an allegedly radium-laced core."

While I can’t substantiate his date of 1910, I can confirm that the radium core was real. A gamma spec analysis clearly shows that the ball contains radium: approximately 150 Bq (4 nCi).

Patent for the Radio Golf Ball

The relevant patent (1,260,788) was applied for in 1916 by Ellis Miller and assigned to the Radium Golf Ball Company of New York.

Before the patent was granted (in 1918), Miller’s golf ball was described in the November 15, 1916 issue of the India Rubber Review as follows

"There is provided within the improved ball... a radio-active substance or mixture, such, for example, as a uranium mineral or ore (e.g., pitchblende), or the intensely radio-active bodies known as radium, polonium, actinium, mesothorium, and the like.

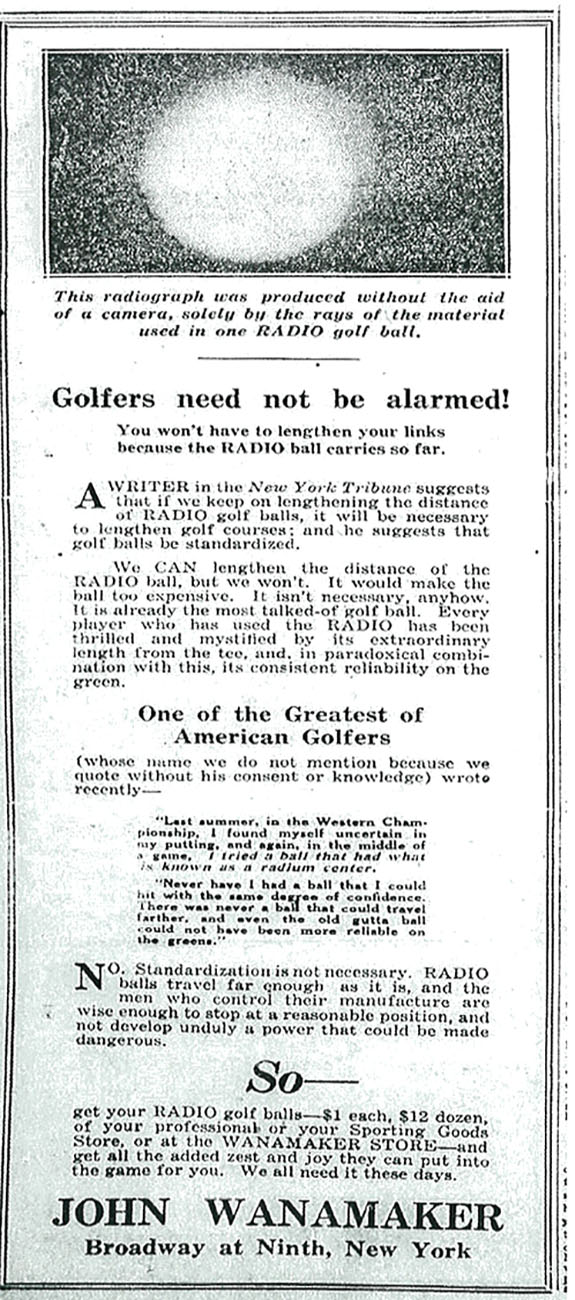

Advertisements for the Radio Golf Ball

Quoting Robert Hartman's Tales from Pinehurst: Stories from the Mecca of American Golf:

"The Radio golf ball was advertised as, "The Ball of Mystery that never loses life or shape due to its inherent radioactive properties."

The earliest explicit reference to the "Radio" Golf Ball I that have found was an ad in the June 30, 1917 issue of the Philadelphia Enquirer:

“And the New Radio Golf Ball embodying the first improvement that has been made in a golf ball since the rubber core... $1 each, $12 a dozen”

The last advertisement for the Radio Golf Ball that I could locate was from 1925 (Detroit Free Press, April 15, 1925) by which time the price had dropped to 45 cents.

Construction of the Radio Golf Ball

The most detailed description of the “Blue Radio Golf Ball” can be found in an advertisement taken out by Wannamaker Company. Selective quotes follow:

“There are thirty operations, and it takes about six months.”

“The center is plastic—composed of a specially compounded rubber and a quantity of active radium salts.”

“A length of pure para rubber tape, one inch wide, is then wound by hand to the plastic center, under tension, forming a small, hard core about a half inch in diameter.”

The center was then increased to a larger size in a winding machine using pure para rubber thread.

“The outer cover is composed of highest grade South American Balata Gum, refined with infinite care and secret processes.”

After vulcanizing, the ball:

“is buffed, washed, treated and cured... Painting and varnishing are done with the palms of the hands.”