Thorium Containing Welding Rod (1990s)

These thoriated "welding rods" are really electrodes of the type used in tungsten inert gas (TIG) welding. The rod is consumed during use, but it does not act as a filler that binds two pieces of metal together. The rate of consumption is approximately 0.1 to 0.3 mg/minute for typical currents but it can be as high as 50 to 60 milligrams per minutes for the maximum rated currents. This consumption probably involves volatilization and the loss of tiny droplets at the electrode tip. Because TIG welding is expensive, its is limited to those situations that require high quality results (e.g., the aircraft and petrochemical industries).

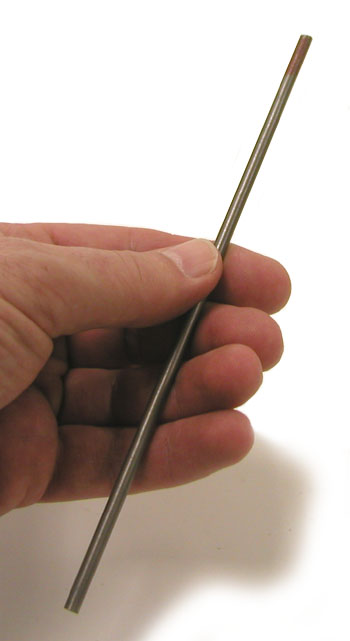

By weight, the rods are usually 1 or 2% thorium oxide (thoria) although higher concentrations, up to 4%, have been used. The rods are color coded to indicate the thoria content: yellow indicates 1%, and red indicates 2%. The color usually appears as a band at one end of the rod (like that in the photo to the right). While they range from 0.25 to 6.35 mm in diameter and 7.6 to 61 cm long, a “typical” rod would be about 2.4 mm in diameter, 15 cm long, and contain 0.23 grams of thorium. Estimates over the last two decades put the annual production at 1 to 5 million electrodes.

Thorium is added to the tungsten because it increases the current carrying capacity of the electrode and it reduces contamination of the weld. In addition, it is easier to start the arc and the latter is more stable.

The radiological concern is the inhalation of airborne thorium. Thorium gets into the air because of the volatilization discussed earlier and the grinding that is necessary to put a point on the electrode prior to use. As a result of this concern, it is expected that the thorium in the rods will eventually be replaced by lanthanum or cerium oxide.

Airborne Thorium Concentrations

During welding operations, Ludwig et al measured thorium concentrations of < 7 x 10-9 to 5 x 10-6 uCi/m3 with a geometric mean of 3 x 10-8 uCi/m3. The concentrations measured during AC welding operations were approximately 30 times those measured during DC welding.

Vinzents et al. measured a respirable concentration of 2 x 10-5 uCi/m3 during the grinding of rods with a 4 % thorium content (the respirable fraction was 0.3). The conditions selected for the study were a “worst case” scenario. Ludwig et al reported an airborne concentration of 5 x 10-6 uCi/m3 during the grinding. Crim and Bradley reported 6.3 x 10-7 uCi/m3 while Jankovic et al reported 1.4 x 10-6 uCi/m3. Based on this data, NUREG-1717 concluded that a typical concentration during grinding was 2.3 x 10-6 uCi/m3.

Dose Estimates

Detailed dose estimates are described in NUREG-1717. The conclusion was that the maximum individual doses resulted from routine welding and grinding operations. The estimated doses due to transportation and distribution were relatively small.

1. Doses from Grinding

The grinding of the rod to form a pointed end can take anywhere from 20 to 60 seconds depending on the skill of the grinder. For welders that grind their own rods, this can take a minute or even longer. Individuals who specialize in this activity can complete the task much quicker. At a large facility, e.g., with 50 welders, a grinder might handle as many as 150 rods per day (ca. 3 per day per welder). For the purpose of the calculations, NUREF-1717 assumed that the particle size AMAD was 1 um.

An individual welder sharpening his own rods was estimated to receive 20 mrem per year. This would be reduced by a factor of ten or so if a local exhaust system was used.

A dedicated grinder sharpening rods for 200 hours per year without the benefit of a local exhaust system was estimated to receive approximately 800 mrem.

2. Doses from Welding Operations

As NUREG-1717 acknowledges, any estimation of the dose due to welding operations is highly speculative. Assumptions have to be made about the amount of thorium becoming airborne, the amount of time spent welding, the effect of the welder’s mask, the ventilation rate, the size distribution of the particulates, etc.

Assuming that 1000 hours per year were spent in actual welding operations, NUREG-1717 estimated that the dose would be 20 mrem per year for DC operations and 500 mrem per year for AC operations. These estimates assume that no local exhaust system was used. Should local exhaust be employed, the estimated doses would be a factor of ten or so lower. The external exposure due to beta particles and gamma rays was determined to be an insignificant fraction of the dose due to inhalation.

3. Dose from Carrying Welding Rods in Pocket

The estimated effective dose equivalent to an individual carrying three thoriated welding rods (0.9 g thorium) in a shirt pocket for 2000 hours (40 hrs/week x 50 weeks/year) was 8 mrem.

Pertinent Regulations

10 CFR 40.13 Unimportant quantities of source material (2003)

(c) Any person is exempt from the regulation in this part and from the requirements for a license set forth in section 62 of the Act to the extent that such person receives, possesses, uses, or transfers:...

(1) Any quantities of thorium contained in... (iii) welding rods,

References

- Breslin, A.J., and Harris, W.B. Use of Thoriated Tungsten Electrodes in Inert Gas Shielded Arc Welding – Investigation of Potential Hazard. American Industrial Hygiene Association Quarterly 13 (4); 1952.

- Ludwig, T., Schwab, D., Seitz, G., and Siekmann, H. Intakes of Thorium While Using Thoriated Tungsten Electrodes for TIG Welding. Health Physics 77 (4): 462-469; 1999.

- Radiation Exposure of the U.S. Population from Consumer Products and Miscellaneous Sources. NCRP Report No. 95; 1987.

- Nuclear Regulatory Commission. Systematic Radiological Assessment of Exemptions for Source and Byproduct Materials. NUREG-1717. June 2001.